We know your boiler

Your trusted Marine Boiler Service Partner

Automation - Repair - Spare Parts

Global Boiler Aalborg

Your marine boiler service assistance - We Know your boiler

Global Boiler Aalborg specializes in marine boiler service and assistance that helps our customers with all their needs to enhance and prolong the life of their boilers. Our team of professionals is available to assist with automation, repairs, and spare parts.

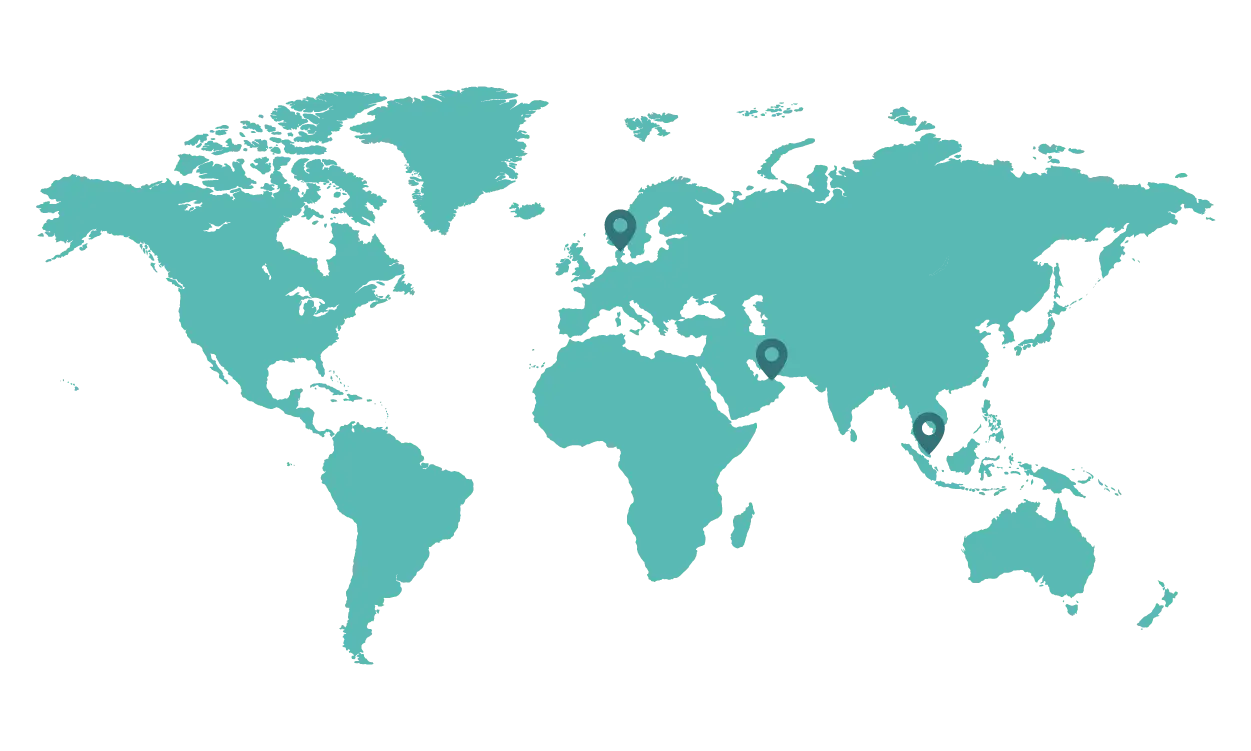

With strategically located branches in Denmark, Dubai, and Singapore, we are your global partner, ready to serve you wherever you are in the world, whenever your boiler requires attention.

As we have extensive industry experience, we can assist you regardless of the service you require. Having had extensive experience in the field of marine boiler service, we are confident when we say: we know your boiler!

Why Choose Us?

Unparalleled Industry Knowledge: With decades of experience in the marine boiler service industry, we have an in-depth understanding of your boiler’s unique needs. We know your boiler inside and out, ensuring top-grade service every time.

Expert Boiler Engineers: Our team of highly qualified boiler engineers is equipped to handle any service requirement with precision and efficiency, from automation to complex repairs.

SOS Service: Emergencies can happen at any time. With our SOS service, we dispatch a dedicated team to your location swiftly, ensuring minimal downtime and maximum peace of mind.

Global Reach: No matter where you are, our global presence means we’re never too far away to assist you promptly.

Contact us

Our Services

Automation

Some aspects of running your boiler can be very time-consuming and require a lot of resources to maintain. With our automation service, you can not only save time and resources but also extend the lifespan of your vessel’s boiler.

Do you need help regarding automation service? Click below for more information.

Repair

A running boiler is bound to need repair at some point. This process can be very tedious and we are ready to make it as smooth as possible. Our expert boiler engineers are able to undertake fabrication in our workshop and repair onboard your vessel.

Are you in need of repair? Click below for more information on our repair services.

Spare Parts

Are you in need of a spare part for your vessel’s boiler? When a part needs replacement, it can escalate into your boiler running at a lower output and wasting resources. We offer a wide range of spare parts for different uses and from different brands.

Do you want to know more about our wide range of spare parts? Click below more information.

Is your marine boiler in need?

Then we are here to help!

We specialize in every boiler need. Do you want high quality service from experienced professionals?

Then you should get in touch with us because we know your boiler.

Click below to find out more.